Personally, I believe that a competently designed bike on (very) wide tyres operating at a (very) low pressure, and preferably fitted with a Brooks (or workalike) hammock saddle plus ergonomically sound handle-bars and -grips, doesn't need an additional old-fashioned suspension fork until you ride it in challenging offload situations, which I don't do, though some of my lanes are plenty rough.

In any case, suspension forks in the normal course of their operation change the bike's steering geometry adversely every time they compress or rebound, which is unacceptable. The only correctly designed suspension fork of which I'm aware, long unobtanium, was designed and sold for some years by a French motor racer; it basically used the head tube as the fixed strut and offset the suspended part of the assembly by two unequal length and non-parallel A-frames working around the head tube, arranged so that the moving forks at all times operated only perpendicular to the ground, so preserving the designer's intended steering (and, important, roadholding and handling) geometry without possibility of exception. I was outbid for the last NOS version of it. I can't remember the name (Cobra?) and can't find a photo of it. Instead I show you a Honda Goldwing front suspension design, which isn't anywhere near as clear. You'll have to take my word for it that the French bicycle version was a lot smaller, lighter, neater. For a decade or two it was the ne plus ultra for every Continental downhill bomber, a genuinely grown-up suspension system. Here's the stand-in Honda Goldwing independent front suspension.

Honda Goldwing independent front suspension with a high degree of isolation from the road.

Image courtesy Honda.

Note that the steering tube is isolated from the suspension mechanism. You can clearly see the top A-frame surrounding the steering tube and fixed to the moving struts of the suspension. The spring and damper sit on the lower A-frame, so it is not immediately obvious.

***

The suspension fork on my Gazelle Toulouse failed under 5000km. Unacceptable.

The suspension fork on my Trek L700 Di2 "Smover" (the full auto Di2, not the cut down cyclist-assisted electronics sold for a premium to roadies) is made of sterner stuff. However, the way it operates is to lock out the suspension when the bike starts up or when it is accelerating hard, but at a high sustained speed to offer Colin Chapman's dream of long travel soft springs firmly damped. (This is the opposite of, for instance, the way the air suspension on some Range Rover models operate: it's soft at low speed and firms up with speed or sporting driving.) On the Trek Smover, the way I ride, on undulating (that's putting it kindly) terrain where I'm always either slogging up a hill or speeding down it, the suspension is mainly locked out until I hit a pothole or other obstacle when, in a fraction of a second, it soaks up the two impacts and damps them without dipping so far I suffer a header. That's a great advantage. But the biggest advantage is that the Shimano electronic adaptive fork in the Smover gruppo reacts to micro-vibrations all the time, regardless of what else is going on. A little more about the electronic adaptive fork and its computer control here:

http://coolmainpress.com/BICYCLINGsmover.htmlBasically, my Kranich, the bike with which I replaced the Smover, uses low pressure 622x60 Big Apples to do the same job considerably less expensively.

All of this is intended to keep micro vibrations out of my hands, as I wrote in a post above.

***

This isn't a digression. As teenage and adult hotrodder, I knew for a fact that Ford doughnuts were the best. When my wife's Volvo Estate irritated me with a vibration in the exhaust line after I fitted a 5.7 litre Chevrolet V8 in the place of the agricultural tractor motor this supposedly "luxury car" came with, I asked the best local motor factor to line up the Ford doughnuts for various sizes of Ford cars on the counter, and soon found the right sizes by comparing the Volvo's doughnuts, which I had brought with me. Killed the vibration stone dead, or, more precisely, absorbed it so that I could no longer feel or hear it.

The same idea is basically used on the Thudbuster saddle suspension Dan likes, though with boutique elastomers, necessitated by the limited space and the need for a high profit margin.

Now a reputable and innovative bicycle component maker has taken up the same idea to quiten micro-vibrations (which they call "fluttering" for one of their peculiar niche markets) coming up the fork and into the cyclist's hands.

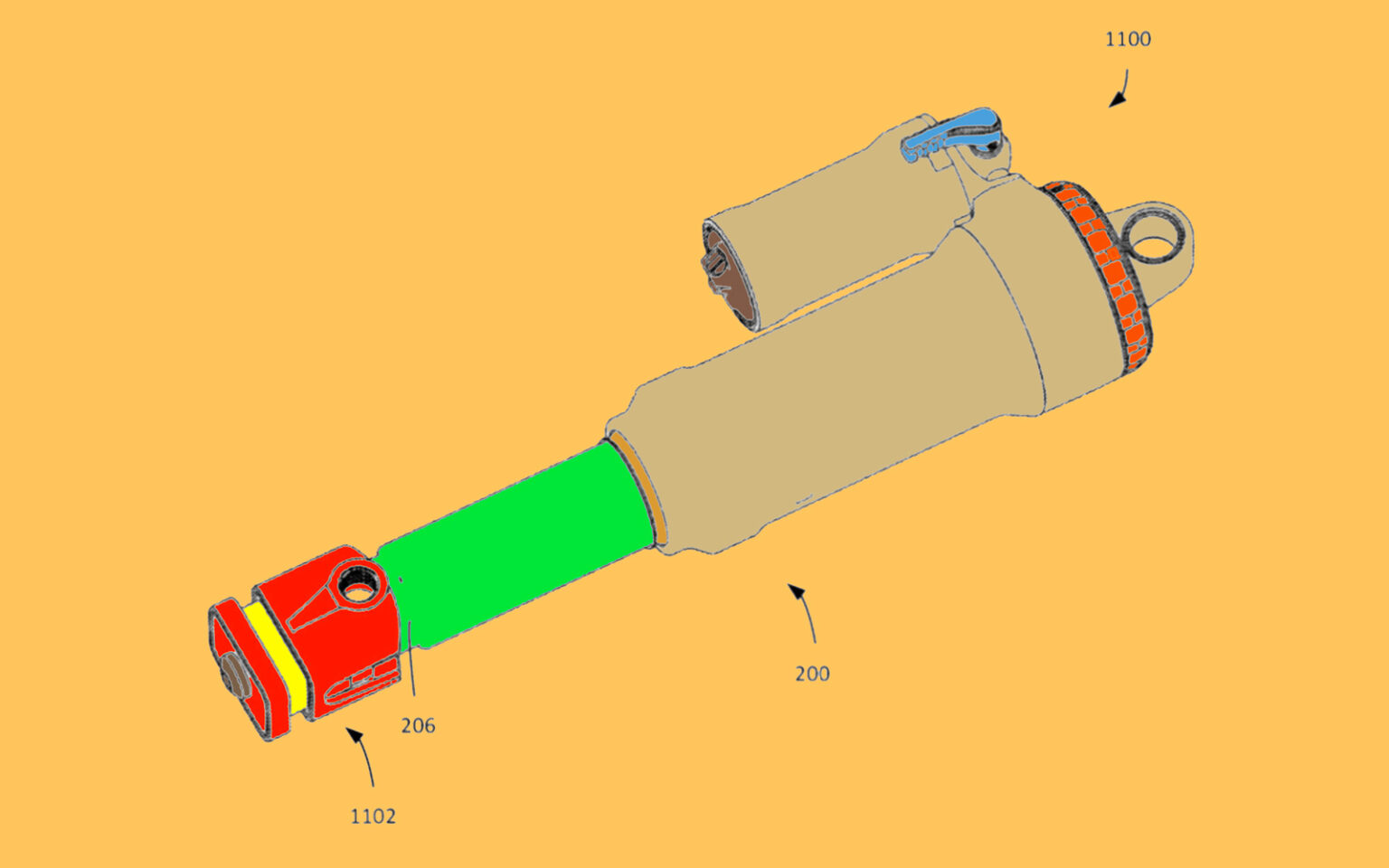

The elastomers are coloured red. Image credit: SRAM.

The article is here for the technically curious:

https://bikerumor.com/utterly-butterly-sram-patents-shock-fluttering-end-mounts/As I said above, I don't really need a suspension fork. But these elastomers on a fixed fork surrounding the axle and at the crown (without the hydraulic bits in between, but instead a normal tube fork) would be tuneable to mop up the very last micro-vibrations that are let through by the Big Apples. (Hey, even paranoids have enemies!) Or imagine a bike on which for some reason you cannot fit a fork wide enough to accommodate true balloons, such elastomers top and bottom of the fork would be a welcome additions, with the substantial advantage over a moving suspension fork that the movement in the elastomers would be so small that the steering geometry is hardly altered, thus obviating the need for a fork with moving parts.

In time the elastomers might even be adapted to the other joints in this micro-vibration transmission line, at the juncture of steering tube and stem, and the juncture of stem and handlebars, and why not at where the steering tube is fixed in the head tube to make the line completely isolated.

Elastomers are cheaper than hydraulic or air suspension and far more tuneable.